Zinc Whiskers: The Silent Risk Threatening Atlanta’s Legacy Data Centers

Most data center failures don’t announce themselves with alarms.

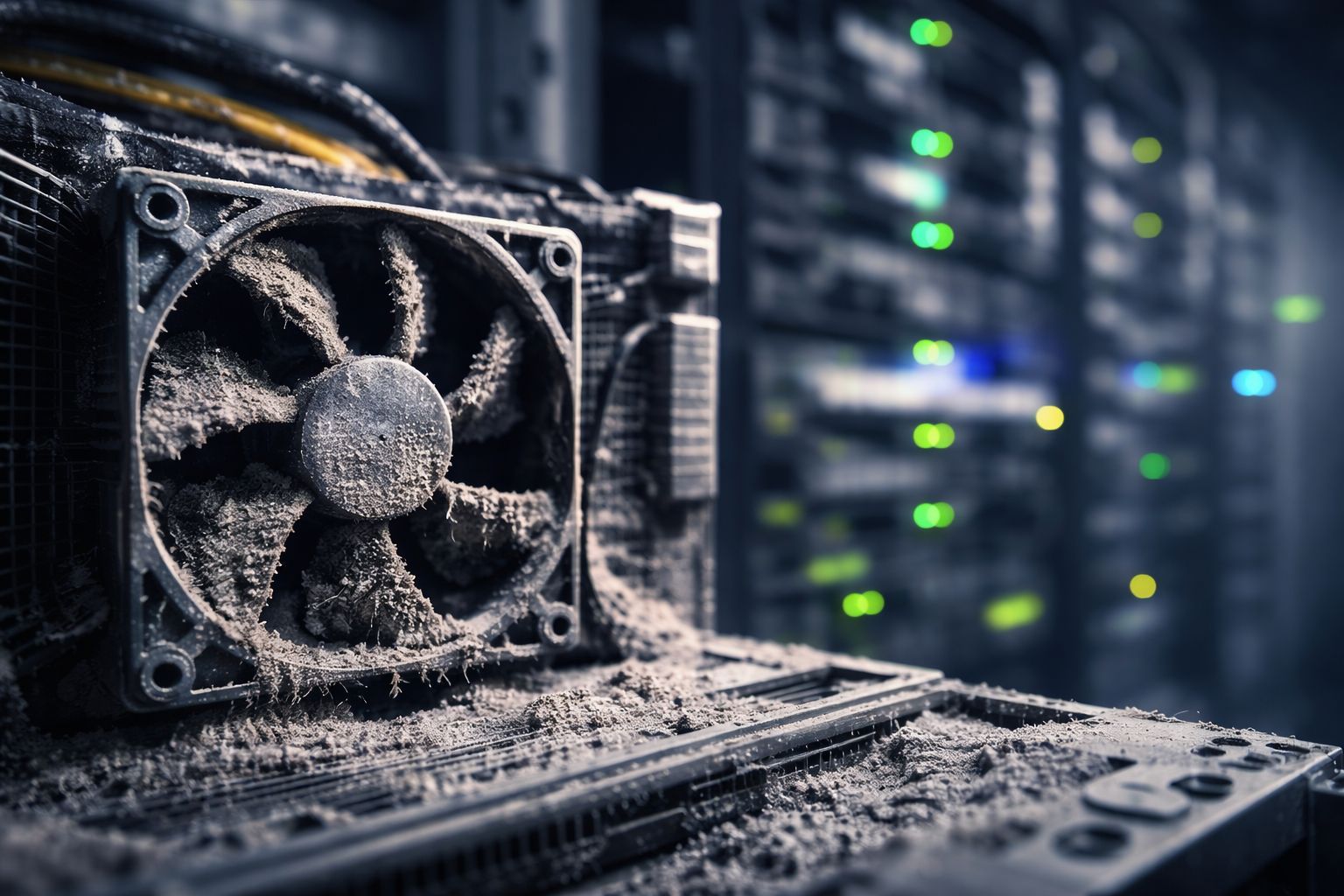

They begin quietly—beneath raised floors, inside aging infrastructure, in places rarely inspected. One of the most dangerous and least understood threats in legacy data centers is zinc whiskers. They are invisible to the naked eye, electrically conductive, and capable of causing catastrophic equipment failure without warning.

For Atlanta’s older carrier hotels, enterprise server rooms, and retrofit facilities, zinc whiskers are not a theoretical concern. They are a documented risk—and one that becomes exponentially more dangerous during renovations, maintenance, or improper cleaning.

This guide explains what zinc whiskers are, why Atlanta facilities are uniquely exposed, how standard cleaning practices make the problem worse, and what proper remediation actually looks like.

What Are Zinc Whiskers?

Zinc whiskers are microscopic, hair-like metal filaments that grow from zinc-electroplated steel surfaces. They typically form on:

- Raised floor tiles

- Subfloor pedestals and stringers

- Cable trays and structural supports

These components were widely used in data center construction during the late 1990s and early 2000s—placing many Atlanta facilities squarely in the risk window.

Unlike corrosion or rust, zinc whiskers are not caused by environmental decay. They are a stress-relief phenomenon within the metal plating itself. Over time, internal stresses force zinc to extrude outward in needle-thin filaments that can reach several millimeters in length.

Individually, they are tiny. Operationally, they are dangerous.

Why Zinc Whiskers Are So Dangerous in Data Centers

Zinc whiskers are electrically conductive. When disturbed, they break off, become airborne, and are pulled into server intakes by cooling airflow.

Once inside equipment, a single whisker can:

- Bridge electrical contacts

- Cause short circuits

- Trigger intermittent failures that leave no forensic trace

- Destroy power supplies, circuit boards, or storage systems

The most damaging aspect is that the whisker often vaporizes during the short, leaving no visible evidence behind. This leads to misdiagnosed failures, repeated equipment replacements, and unresolved root causes.

In mission-critical environments, this isn’t a cleaning issue. It’s an uptime and asset-protection issue.

Why Atlanta Data Centers Face Elevated Risk

Atlanta is one of the largest data interconnection hubs in the Southeast. Many facilities still operating today were built during earlier expansion cycles and have since undergone:

- Tenant churn

- Infrastructure upgrades

- Partial retrofits

- Cable mining and power densification

Each of these activities increases the likelihood of zinc whisker disturbance.

Legacy carrier hotels and older enterprise facilities—particularly those with raised floors installed before modern mitigation standards—are at heightened risk. Renovation periods are especially dangerous, as lifting tiles or performing maintenance can aerosolize accumulated whiskers.

How Improper Cleaning Makes the Problem Worse

This is where many facilities unintentionally create their own failure conditions.

Standard janitorial cleaning methods—appropriate for offices or commercial spaces—are actively dangerous in environments with zinc whiskers.

High-risk practices include:

- Dry sweeping or dusting under raised floors

- Scrubbing or wiping zinc-plated surfaces

- Using non-HEPA vacuums

- Dragging mops or tools across subfloor components

These actions dislodge whiskers in large quantities, turning a contained risk into a facility-wide airborne contamination event.

In other words: the wrong cleaning doesn’t remove the threat—it weaponizes it.

What Proper Zinc Whisker Remediation Actually Looks Like

Zinc whisker mitigation is not cosmetic cleaning. It is a containment-based technical process designed to control particulate movement and protect live environments.

Effective remediation typically includes:

1. Risk Identification & Assessment

- Subfloor inspections using proper lighting techniques

- Targeted sampling when required

- Identification of zinc-plated components and disturbance zones

2. Controlled Containment

- Isolated work zones

- Physical barriers to prevent particulate spread

- Sequenced access protocols

3. HEPA-Filtered Extraction

- Specialized HEPA vacuums rated for fine metallic particulates

- Controlled capture velocities to prevent re-aerosolization

- No dry contact with zinc surfaces

4. Safe Work Methodology

- Lint-free tools and materials

- ESD-safe processes

- Technicians trained specifically for live critical environments

5. Validation & Documentation

- Post-remediation inspection

- Environmental verification where required

- Documentation suitable for facility management and audit review

This process is designed to remove risk without disrupting operations—and without introducing new failure modes.

The Cost of Ignoring Zinc Whiskers

The financial impact of zinc whisker-related failures is rarely limited to a single component.

Unplanned downtime can cascade into:

- Equipment replacement costs

- SLA violations

- Customer outages

- Reputational damage

- Emergency remediation at premium rates

By comparison, proactive assessment and controlled remediation represent a fraction of the cost of even a short outage.

This is why leading facilities treat zinc whisker mitigation as risk management, not maintenance.

Who Should Act Now

Facilities that should proactively assess zinc whisker risk include:

- Legacy data centers with raised floors

- Carrier hotels and interconnection facilities

- Enterprise server rooms built pre-2005

- Data centers undergoing renovation or cable mining

- Facilities preparing for tenant upgrades or commissioning

If your environment fits any of these profiles, waiting for symptoms is not a strategy.

CleanStar’s Approach to Critical Environment Risk

CleanStar does not approach data centers as janitorial accounts.

We operate as a Critical Environment Risk Partner, trained to work inside live, high-consequence facilities where mistakes are unacceptable.

Our teams are equipped, trained, and protocol-driven to:

- Identify contamination risks

- Execute containment-based remediation

- Protect uptime, assets, and operational continuity

Schedule a Critical Environment Risk Audit

If your facility includes raised floors, legacy infrastructure, or upcoming renovation work, a proactive risk assessment can prevent costly surprises.

Schedule a Critical Environment Risk Audit to evaluate zinc whisker exposure, contamination risks, and mitigation pathways—before they become operational failures.

Clean environments protect equipment.

Controlled environments protect uptime.

Prepared facilities protect everything else.