How Dust Contamination Impacts Server Performance and Uptime

In a mission critical data center, environmental control directly influences system reliability. Dust accumulation restricts airflow, increases thermal load and accelerates hardware degradation. Structured contamination control supports cooling efficiency, infrastructure longevity and sustained uptime across North Atlanta facilities.

Precision Infrastructure Requires Environmental Discipline

Data centers are engineered around narrow operational tolerances. Airflow design, thermal regulation and electrical stability function within calibrated limits. When particulate contamination enters the environment, those limits begin to compress.

Dust is not cosmetic. It is operational friction.

In high availability facilities, even incremental airflow obstruction or debris accumulation can compound into performance instability over time.

Airflow Integrity and Thermal Stability

Modern server environments rely on structured airflow management. Raised flooring systems, perforated tiles and rack ventilation pathways regulate temperature under continuous load.

When particulate builds along vent panels, cable trays or subfloor cavities, airflow efficiency declines. Cooling systems compensate by increasing output. Energy demand rises. Thermal margins narrow.

Localized heat concentration accelerates component wear and elevates the probability of hardware failure.

Airflow performance and contamination control are directly connected. Facilities that prioritize environmental discipline protect both system performance and capital investment.

For deeper insight into technical cleaning protocols, see our analysis on Why Data Centers Require Specialized Cleaning Protocols.

Fine Particulate and Hardware Reliability

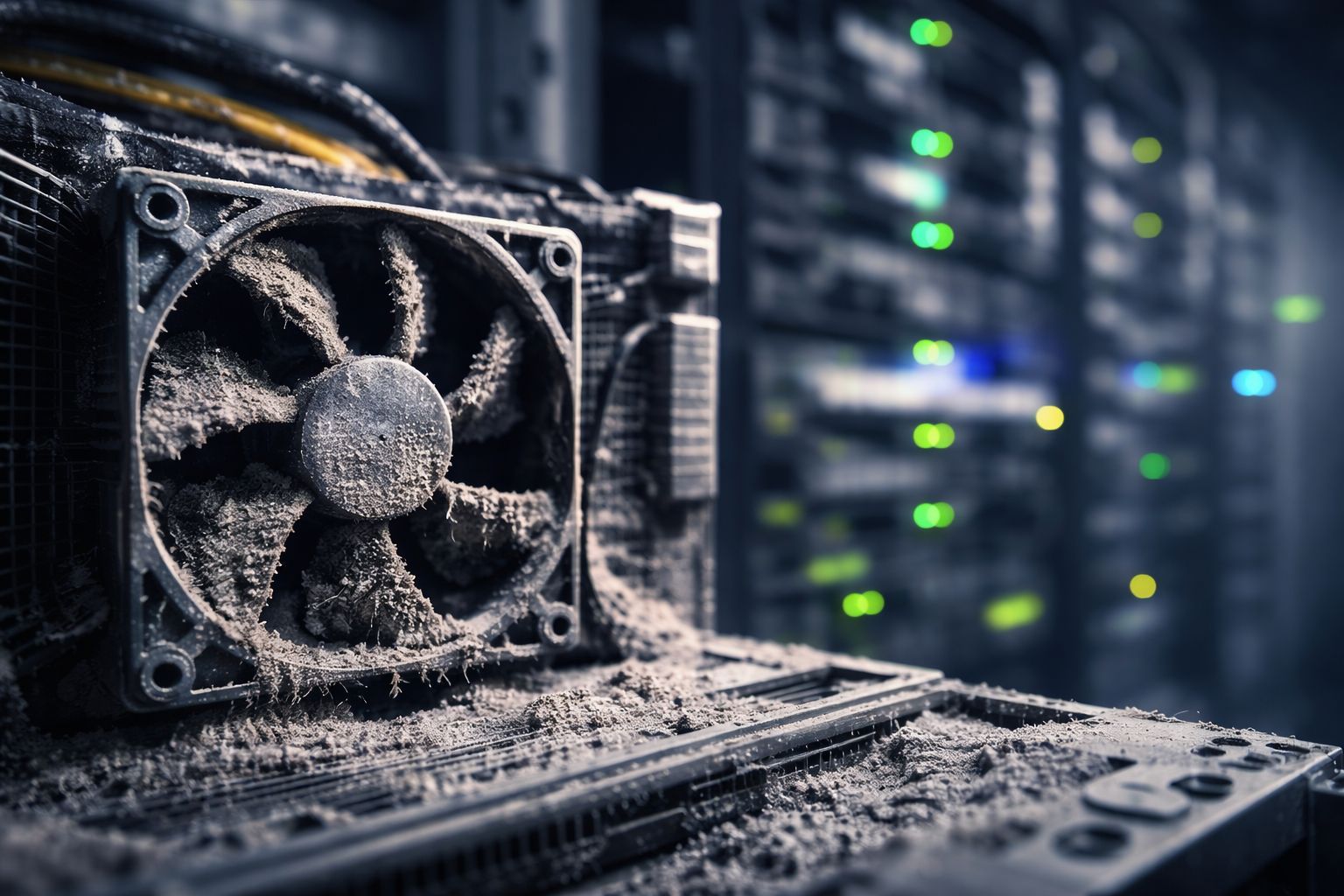

Dust does not remain on visible surfaces. It migrates into vents, fans and internal assemblies. Over time, accumulation interferes with internal cooling systems and obstructs circuitry.

In environments that have undergone renovation or infrastructure upgrades, contamination may include conductive debris. Without proper post construction cleaning, those particles can settle into sensitive hardware components.

This often produces gradual degradation rather than immediate failure. Performance becomes inconsistent. Error rates increase. Preventive maintenance intervals shorten.

We explore electrical risk further in Electrostatic Discharge Risks in Server Environments.

Construction Activity and Deferred Risk

North Atlanta continues to experience expansion in commercial and technical infrastructure. Data centers undergo phased build outs, rack additions and mechanical retrofits.

Each construction phase introduces particulate into the environment. If final technical cleaning is incomplete, debris remains in subfloor systems and along rack exteriors. Once full operational load resumes, airflow redistributes contamination throughout the facility.

Deferred contamination becomes deferred risk.

Structured post construction cleaning is not optional in mission critical facilities. It is foundational to operational readiness.

Uptime Is an Environmental Outcome

Uptime is commonly attributed to redundant power and network architecture. Those systems are essential. But uptime is also environmental.

Stable airflow supports stable temperature. Stable temperature supports hardware longevity. Hardware longevity supports operational continuity.

Contamination control is infrastructure support.

Industry best practices from organizations such as ASHRAE and leading equipment manufacturers emphasize environmental management as a component of reliability. Facilities that treat environmental discipline as an operational standard strengthen resilience.

The Standard for Contamination Control in North Atlanta

Data centers require cleaning methods designed specifically for technical environments. Controlled particulate removal, low moisture procedures and coordinated service windows reduce disruption while protecting sensitive infrastructure.

Across North Atlanta, Cleanstar National supports mission critical facilities with structured contamination control aligned to enterprise standards.

The objective is not surface cleanliness. It is operational stability.

Dust is small. Its operational impact is not.

Technical Questions About Dust Contamination in Data Centers

How does dust affect data center cooling systems?

Dust accumulates on vents, perforated tiles and internal cooling components, restricting airflow and reducing cooling efficiency. When airflow declines, thermal load increases and hardware operates under greater stress.

Can dust buildup cause server failure?

Yes. While dust does not always cause immediate failure, prolonged accumulation can lead to overheating, fan obstruction and component degradation. Over time, this increases the risk of hardware instability or shutdown.

Why is post construction cleaning important in data centers?

Construction activity introduces fine particulate and, in some cases, conductive debris. Without structured contamination control, those particles can settle inside racks and subfloor cavities, creating long term performance risk.

How often should data centers be cleaned to prevent dust related performance issues?

Cleaning frequency depends on facility load, airflow design and nearby construction activity. High availability environments typically require scheduled technical cleaning to maintain airflow integrity and environmental control.

Does dust impact energy efficiency in data centers?

Yes. Restricted airflow forces cooling systems to work harder, increasing energy consumption. Maintaining contamination control helps support efficient thermal management and reduces unnecessary strain on infrastructure systems.

Is general janitorial cleaning sufficient for server rooms?

No. Server rooms require controlled particulate removal, low moisture methods and equipment safe procedures designed specifically for technical environments.