Electrostatic Discharge Risks in Server Environments

Facility leaders should evaluate static mitigation practices carefully. See what facility managers should look for in a data center cleaning partner.

Electrostatic discharge can damage sensitive server components without visible evidence. In high availability data centers, unmanaged static risk threatens hardware reliability, operational continuity and long term infrastructure stability. Structured ESD aware cleaning and environmental control protocols reduce exposure and protect mission critical performance.

The Invisible Risk Inside Technical Environments

Electrostatic discharge is often misunderstood. It is not dramatic. It does not announce itself.

It is silent, instantaneous and capable of degrading sensitive electronic components at the microscopic level.

In a server environment where thousands of integrated circuits operate continuously, even a small discharge can compromise component reliability. Damage may not appear immediately. It may manifest months later as unexplained instability, reduced performance or premature hardware failure.

In mission critical facilities, unseen risk is still risk.

What Causes Electrostatic Discharge in Data Centers

Static electricity forms when two surfaces separate and exchange electrons. In commercial environments this may be minor. In technical environments dense with circuitry, it becomes consequential.

Common contributors include:

- Low humidity conditions

- Uncontrolled movement across raised flooring

- Improper cleaning equipment

- Non grounded vacuum systems

- Construction debris and particulate

Raised floor systems, while essential for airflow management, can increase static accumulation if environmental controls are not carefully maintained.

When static energy discharges into sensitive equipment, it can weaken or damage internal components.

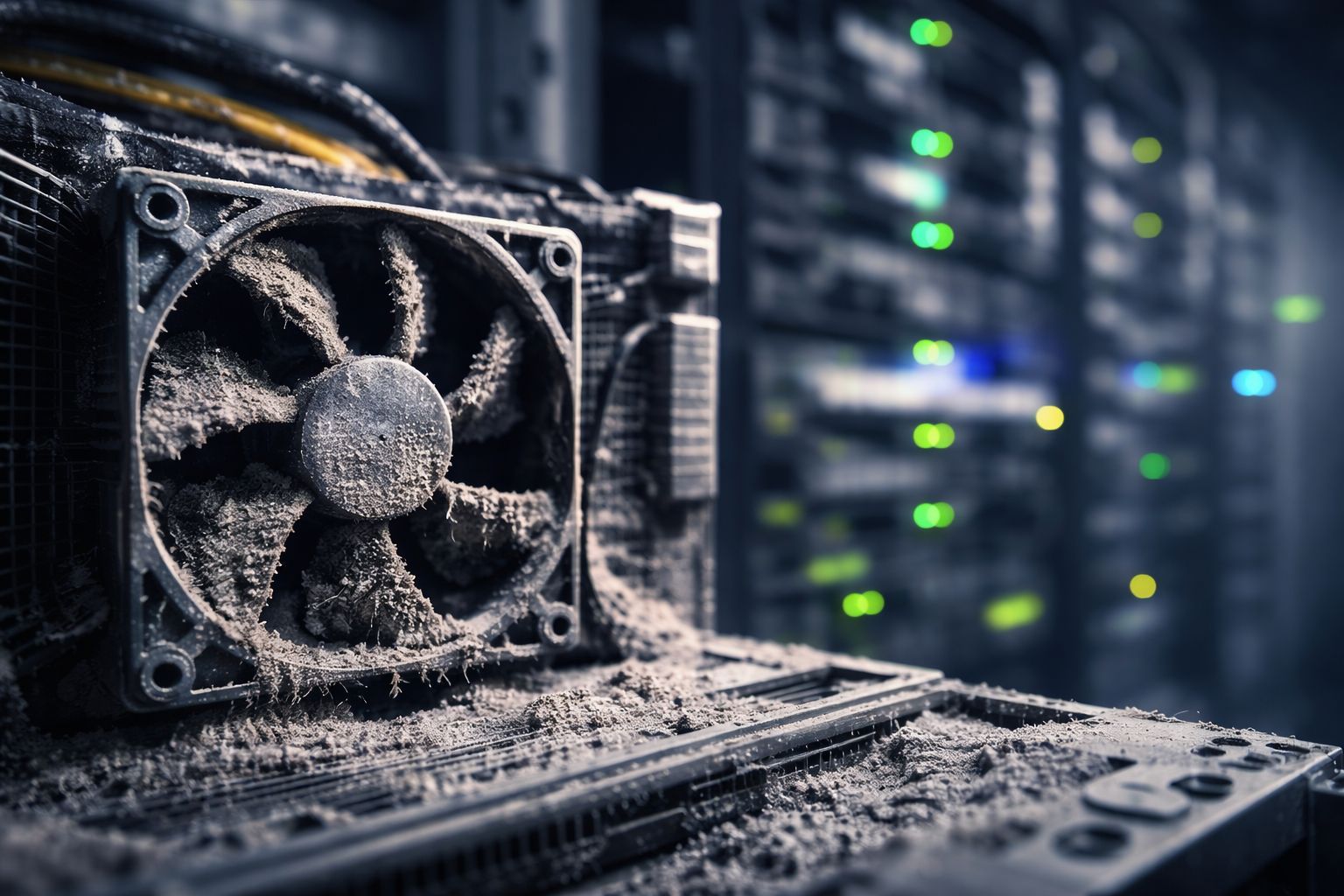

Static risk is often compounded by particulate accumulation. See how dust contamination impacts server performance and uptime.

Why Standard Cleaning Methods Increase ESD Risk

Traditional commercial cleaning practices are not designed for electronic density.

- Unfiltered vacuums can generate static.

- Improper materials can create friction.

- Uncontrolled access can introduce static discharge potential.

In environments where servers operate continuously, friction based cleaning without grounding protocols introduces avoidable exposure.

ESD risk is not theoretical. It is procedural.

The Cost of Static Damage

Electrostatic discharge may not cause immediate shutdown. More often, it weakens microcomponents within servers, network switches or storage systems.

The consequences may include:

- Intermittent system errors

- Reduced hardware lifespan

- Unexpected equipment replacement

- Data integrity concerns

- Increased maintenance intervals

In mission critical environments, reliability is measured over years, not hours. ESD damage undermines that reliability silently.

Downtime is rarely attributed directly to static. It is often attributed to component failure. The underlying cause may remain unnoticed.

Environmental Controls That Reduce ESD Exposure

Managing static risk requires intentional environmental discipline.

- Humidity control within recommended operating ranges

- Grounded ESD safe cleaning equipment

- Controlled movement across raised floor systems

- Non conductive and low friction cleaning materials

- Structured access protocols during service windows

These measures do not eliminate static entirely. They reduce the probability of discharge affecting sensitive hardware.

ESD control is preventive risk management.

Construction and Retrofit Considerations

Server environments frequently undergo hardware refresh cycles, cable tray adjustments and infrastructure upgrades. Construction activity introduces particulate and movement patterns that can increase static accumulation.

Without structured post construction technical cleaning and environmental reset procedures, static exposure risk increases.

Facilities transitioning from construction to operational load should treat ESD control as part of readiness verification, not an afterthought.

ESD Risk and Operational Continuity

In enterprise facilities across North Atlanta and similar technical markets, uptime is non negotiable.

Environmental variables contribute directly to performance continuity. Static discharge is one of those variables.

While redundancy protects against catastrophic failure, disciplined environmental management protects against silent degradation.

Specialized cleaning protocols that incorporate ESD awareness support long term infrastructure resilience.

The objective is not visual cleanliness. It is system stability.

Technical Questions About Electrostatic Discharge in Server Environments

What is electrostatic discharge in a data center?

Electrostatic discharge occurs when built up static electricity transfers from one surface to another. In data centers, this transfer can damage sensitive electronic components.

Can ESD cause immediate server failure?

Yes, though more commonly it causes microscopic component damage that leads to performance degradation or early hardware failure over time.

Does humidity affect ESD risk?

Yes. Lower humidity increases static accumulation. Maintaining recommended environmental humidity levels helps reduce discharge probability.

Are regular vacuums safe in server rooms?

No. Non ESD rated vacuum systems can generate static during operation. Data centers require grounded, ESD aware equipment designed for electronic environments.

How can facilities reduce ESD exposure during cleaning?

Using grounded equipment, maintaining humidity control, limiting friction based methods and following structured technical cleaning protocols significantly reduces static risk.

Closing Perspective

Electrostatic discharge is not dramatic. It does not leave visible residue. It does not trigger alarms.

Its damage accumulates quietly.

In server environments where uptime defines operational credibility, invisible risk deserves visible discipline.

Specialized ESD aware cleaning protocols are not optional enhancements. They are part of responsible infrastructure management.

Mission critical facilities demand nothing less.