World Cup 2026 Readiness: How Atlanta Facilities Must Prepare for Continuous Operations

World Cup 2026: The Operational Reality Facing Atlanta Facilities

In 2026, Atlanta will not host a moment.

It will host sustained global attention.

For weeks, the city’s infrastructure will operate under conditions few facilities ever experience: continuous foot traffic, extended operating hours, heightened public scrutiny, and no tolerance for visible failure. Stadiums, transportation hubs, healthcare facilities, government buildings, hotels, and commercial venues will all be experienced repeatedly—by millions of visitors, international media, and global stakeholders.

For facility leaders, the FIFA World Cup is not a branding opportunity.

It is an operational reckoning.

The question is not whether facilities will be busy.

The question is whether they are prepared to operate continuously, visibly, and without error.

Why the World Cup Is a Facility Stress Test, Not an Event

Large international events expose weaknesses that routine operations often conceal.

During the World Cup, facilities face conditions that compress months of wear into days. Restrooms cycle through thousands of users per hour. Floors never fully rest. Waste streams exceed standard assumptions. High-touch surfaces become public-health variables rather than routine maintenance items.

Facilities that rely on traditional janitorial schedules struggle under this pressure. Those that perform well operate with event-grade protocols designed for endurance, not appearance.

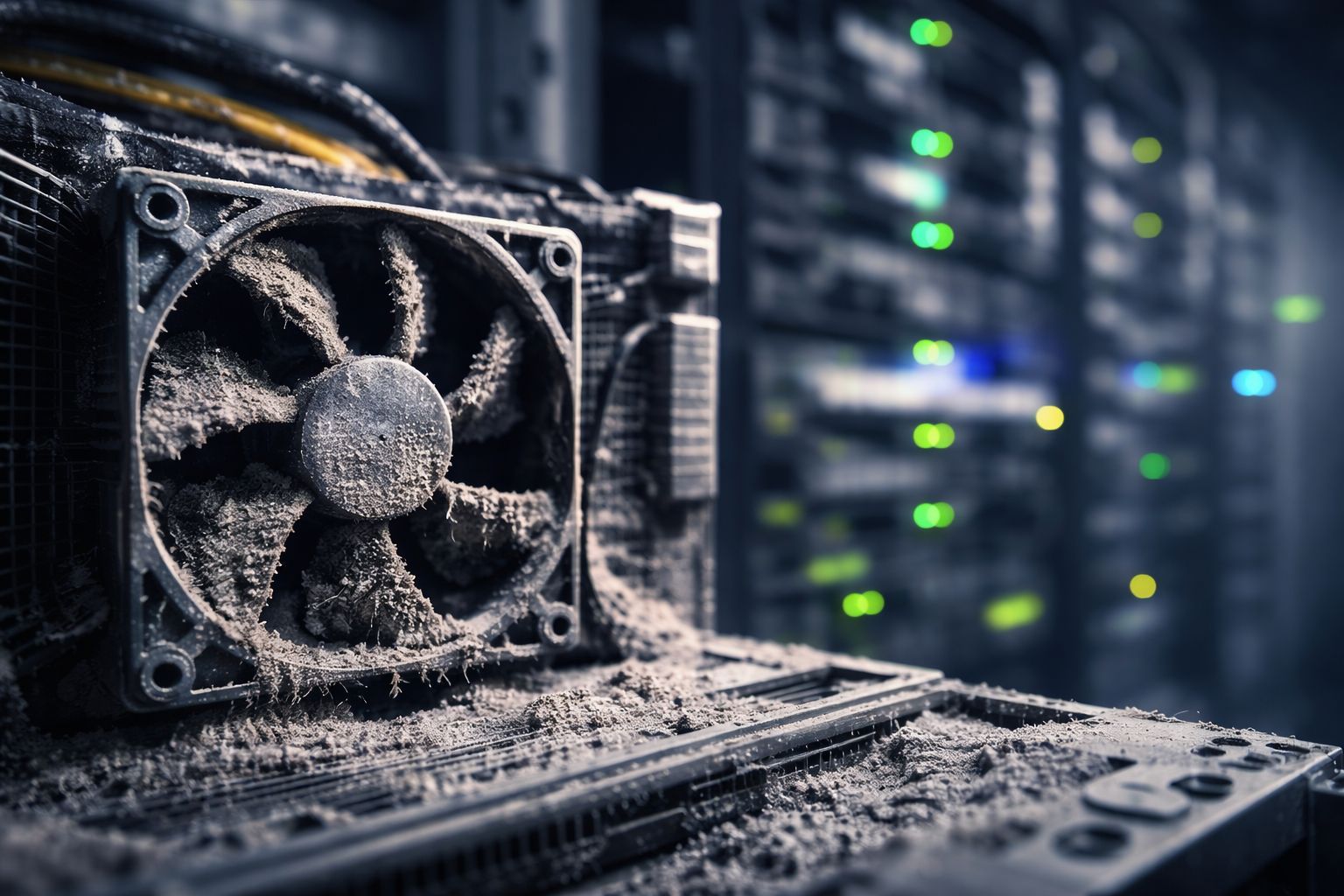

This distinction is especially critical in mission-critical environments such as healthcare facilities, data centers, and transportation hubs—spaces where safety, continuity, and compliance are inseparable from cleanliness.

From Scheduled Cleaning to Continuous Operations

Traditional cleaning models are built around intervals: morning preparation, nightly resets, periodic deep cleaning. World

Cup conditions eliminate those gaps.

Facilities that maintain control during global events shift from scheduled cleaning to continuous operational support.

This is not about cleaning more frequently. It is about operating differently.

Under a continuous model:

- Cleanliness is maintained rather than restored

- Supplies are replenished before depletion

- Issues are resolved before they are noticed

- Cleaning teams function as part of the live operational environment

This approach mirrors how Cleanstar National supports mission-critical facilities, where uptime, safety, and reliability matter more than cosmetic outcomes.

Restrooms: The First Point of Judgment

No area influences visitor perception faster than restrooms.

During high-volume events, restrooms become pressure points. A single failure—empty dispensers, overflowing trash, lingering odors—can undo hours of otherwise strong facility performance.

World Cup readiness guidance emphasizes a rapid refresh protocol, often cycling restrooms every 15 to 20 minutes during peak demand. These refreshes are not full cleans; they are disciplined resets focused on:

- Product availability

- Touchpoint sanitation

- Visual order

- Odor prevention

Globe Chemical outlines this operational standard in detail in The World Cup Cleanliness Standard: A 24-Hour Day Porter Protocol for Atlanta Facilities.

Facilities already operating under professional day porter programs are structurally better prepared to support this model, as it requires constant presence rather than episodic service.

Strategic Waste Stream Management Under Event-Scale Load

Waste is often underestimated during large events.

Overflowing bins are not just unsightly; they create safety risks, disrupt foot traffic, and undermine public confidence.

During the World Cup, waste volume spikes unpredictably and must be managed proactively.

Event-ready facilities treat waste as a flow problem, not a pickup task. That means:

- Using durable liners designed for heavy food and beverage waste

- Enabling rapid liner replacement without removing containers from service

- Transporting waste discreetly through crowds using covered equipment

- Scheduling large removals during natural lulls in activity

When waste handling is visible, it becomes part of the experience.

When it is invisible, it supports the experience without competing for attention.

High-Touch Surface Disinfection in a YMYL Environment

Public health expectations have permanently shifted.

In the context of a global event, high-touch surfaces—handrails, kiosks, elevator controls, counters—become shared contact points for visitors from around the world. These surfaces are no longer housekeeping concerns; they are YMYL (Your Money or Your Life) variables.

World Cup readiness requires facilities to map movement patterns—how people enter, pause, queue, and exit—and disinfect those contact points continuously.

This risk-based approach is detailed in

World Cup 2026: Atlanta Facility Cleaning Protocol.

Effective disinfection in this environment balances efficacy with speed, allowing surfaces to remain safe without disrupting operations. This same discipline underpins Cleanstar National’s medical and healthcare facility cleaning services, where infection prevention and operational continuity must coexist.

Designing the 24-Hour Shift Architecture

World Cup operations are not sustained by adding headcount alone.

Facilities that perform well under prolonged pressure design shift architectures that protect quality over time. These typically include:

Preparation phases

Focused on deep cleaning and full restocking before the first wave of visitors.

Agile response phases

Dedicated to constant monitoring and rapid intervention in high-impact zones.

Recovery phases

Focused on floor care, waste removal, and system resets overnight.

This structure reduces fatigue, limits errors, and ensures standards remain consistent across weeks of continuous use. Facilities accustomed to industrial and high-traffic environments often adapt more effectively to this level of endurance.

What Happens When Facilities Do Not Prepare

The consequences of under-preparation are rarely dramatic in isolation. They accumulate quietly.

A restroom that falls behind once becomes a pattern. A delayed waste pull creates congestion. Missed disinfection cycles compound risk. Staff fatigue leads to errors that would not occur under normal conditions.

Under global scrutiny, these failures are not forgiven as “busy days.” They are interpreted as systemic weaknesses.

Facilities that do not prepare often face:

- Staff burnout and turnover during the event

- Reactive purchasing and inconsistent supplies

- Escalating complaints and visible disorder

- Increased risk exposure without time to correct course

The cost is not limited to the event itself. Recovery after weeks of sustained strain often requires significant remediation.

Different Facility Types, Different Risk Profiles

World Cup readiness is not one-size-fits-all.

Healthcare facilities face heightened infection-control scrutiny while managing normal patient care alongside visitor traffic.

Transportation hubs must balance sanitation with uninterrupted flow and security requirements.

Hospitality and mixed-use venues experience constant turnover, limited downtime, and reputational exposure that extends well beyond the event.

Government and public buildings carry added expectations around safety, accessibility, and public trust.

Each environment requires tailored protocols—but all require early planning.

The Hidden Risk: Supply Chain Assumptions

One of the most common failures ahead of major events is assuming supplies will remain available under surge demand.

During global events, supply chains tighten. Familiar products become scarce. Substitutions introduce inconsistency and training gaps.

Facilities that prepare early standardize systems well in advance:

- Approved products are selected and tested

- Staff are trained on consistent materials

- Inventory levels reflect sustained demand rather than normal usage

- Replenishment schedules are planned, not improvised

Consistency becomes a form of risk management.

Atlanta’s Sustained Exposure

Atlanta’s role as a host city brings layered complexity.

Facilities will not be experienced once, but repeatedly—by visitors staying for days, media crews moving between venues, and partners comparing cities across the tournament. Small issues compound quickly. What might be overlooked during a one-day event becomes noticeable over time.

Facilities that succeed will not draw attention to themselves. They will simply function—quietly, reliably, and without visible strain.

That is the highest operational compliment.

Preparing Now Is a Leadership Decision

The most important decisions about World Cup readiness will not be made in 2026.

They are being made now—through planning cycles, staffing strategies, training programs, and operational audits. Facilities that act early gain time to test systems, refine protocols, and address weaknesses before the world arrives.

Those that wait will be forced into reactive decisions under global scrutiny.

After the World Cup: The Long Tail Few Plan For

The end of the tournament does not mean the end of impact.

Facilities often experience deferred wear, staff exhaustion, and accumulated maintenance demands after large events conclude. Those that planned early recover faster and at lower cost.

Preparation is not only about surviving the event.

It is about protecting the facility’s long-term performance.

What Will Be Remembered

When the World Cup leaves Atlanta, headlines will fade quickly. Impressions will not.

Visitors may not remember individual cleaning teams.

They will remember how the city felt.

Facilities that remained clean, orderly, safe, and reliable under extraordinary conditions will have contributed to Atlanta’s legacy on the world stage.

World-class events demand disciplined preparation.

Quiet execution.

And systems built to last.

That work begins long before the first match is played.