ISO 14644-1 Explained: What Atlanta Facility Managers Must Know About Particle Control in Mission-Critical Environments

For decades, “clean” was judged by what you could see.

Floors shined. Surfaces were wiped. Dust disappeared from view.

In mission-critical environments, that definition no longer holds.

Today, clean is measurable. It is defined by particle counts, airflow behavior, and risk tolerance—not appearance. For Atlanta facility managers overseeing data centers, cleanrooms, healthcare infrastructure, and other high-value technical facilities, this shift is not theoretical. It is operational reality.

At the center of that shift is ISO 14644-1, the international standard governing air cleanliness in controlled environments.

Understanding what this standard actually means—and where facilities commonly fall short—is now part of responsible facility leadership.

What ISO 14644-1 Actually Governs (In Plain Language)

ISO 14644-1 is not a cleaning guideline.

It is an engineering standard.

Specifically, it defines how clean the air inside a controlled environment must be, based on the number and size of airborne particles per cubic meter.

Unlike traditional janitorial benchmarks, ISO 14644-1 does not care whether a surface looks clean. It cares whether particulate matter exists at levels that can:

- Disrupt airflow

- Degrade sensitive equipment

- Trigger static discharge

- Compromise compliance or uptime

In other words, ISO 14644-1 governs risk.

Facilities commonly governed by this standard include:

- Data centers and server rooms

- Cleanrooms and life-science laboratories

- Medical and pharmaceutical manufacturing environments

- Technical facilities where failure carries financial or operational consequences

In these environments, cleanliness is no longer cosmetic.

It is functional.

ISO Class Levels: Why Most Atlanta Facilities Operate at Class 8

ISO 14644-1 defines multiple cleanliness classes. The lower the class number, the cleaner the air.

Most mission-critical facilities in Atlanta operate at ISO Class 8, which allows:

- Up to 3,520,000 particles ≥ 0.5 microns per cubic meter

This class is commonly used in:

- Live data halls

- Server rooms

- Controlled technical environments

- Post-construction commissioning phases

Higher-grade environments—such as ISO Class 7 or cleaner—are typically found in pharmaceutical manufacturing, medical device production, or specialized laboratory zones.

The key takeaway for facility managers is this:

ISO compliance is not static.

A facility can meet ISO Class 8 conditions one day and quietly drift out of compliance the next—often without visible warning.

Where ISO Conditions Commonly Fail in Real Facilities

ISO failures rarely happen because a facility “wasn’t cleaned.”

They happen because the wrong methods were used.

In Atlanta’s built environment, the most common failure points include:

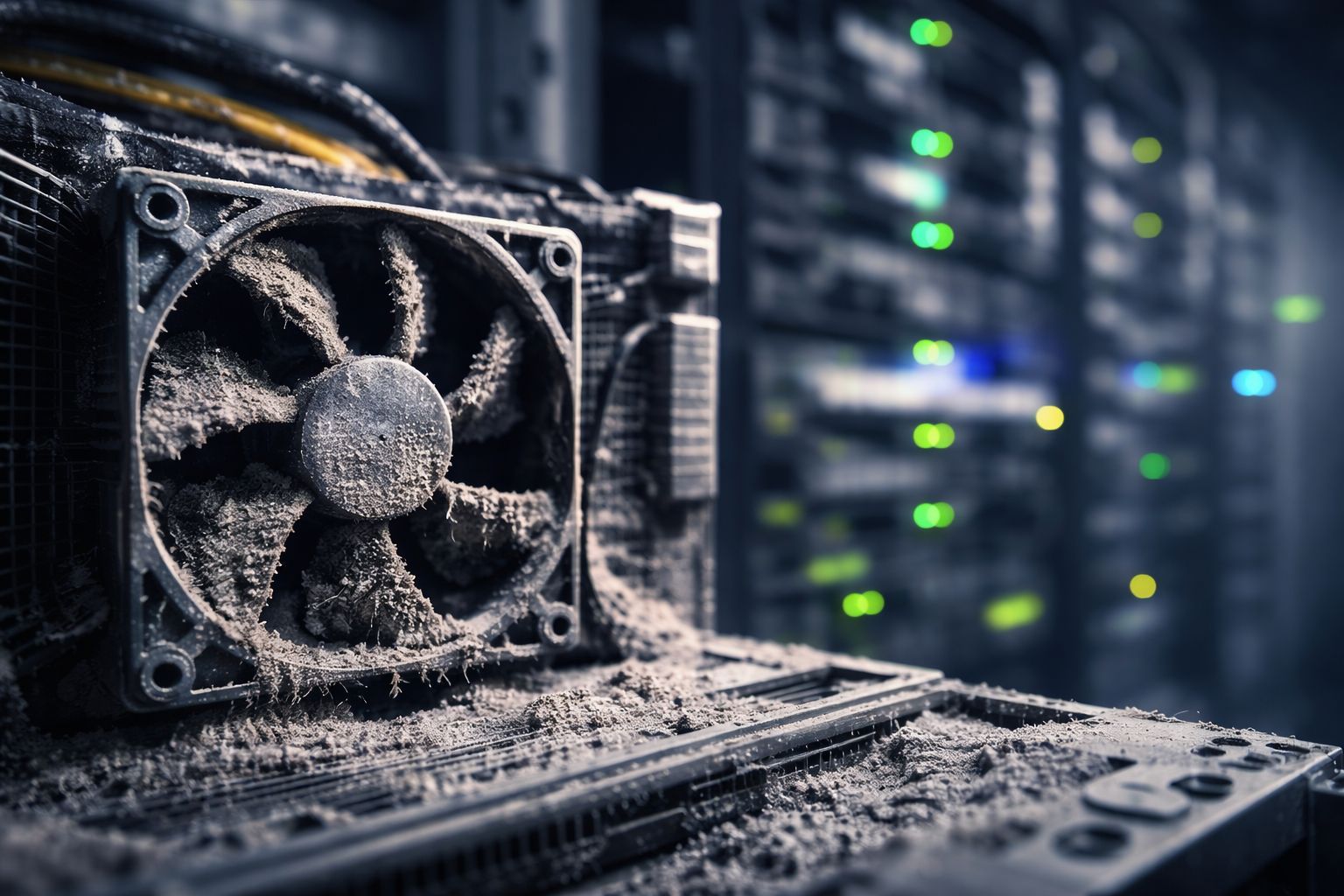

1. Raised Floors and Subfloor Plenums

Subfloor spaces often contain legacy materials, construction debris, or particulate buildup that becomes airborne when disturbed. Improper cleaning here can worsen contamination rather than reduce it.

2. Post-Construction Dust

Concrete dust, drywall particulate, and metal filings are among the most damaging contaminants introduced during construction or renovation. If not removed using ISO-aligned methods, these particles migrate into live systems.

3. Zinc Whiskers and Legacy Infrastructure

Older facilities—particularly legacy data centers—may contain zinc-plated components beneath raised floors. When disturbed, microscopic conductive filaments can become airborne and damage sensitive electronics.

4. Improper Equipment and Materials

Standard vacuums, cotton mops, and non-certified cleaning agents can shed fibers or redistribute particles. The result is an environment that appears clean while quietly violating ISO conditions.

In every case, the issue is not neglect.

It is methodology.

Why Traditional Janitorial Services Often Violate ISO Conditions

Most traditional janitorial vendors are trained to clean visible surfaces efficiently. They are not trained to manage airborne particulate risk.

This creates a dangerous gap.

Common violations include:

- Using non-HEPA vacuums that exhaust particles back into the environment

- Dragging dust across surfaces instead of capturing it

- Introducing static-generating materials into sensitive zones

- Cleaning without understanding airflow patterns or containment boundaries

For ISO-governed environments, these missteps introduce unnecessary risk.

What Facility Managers Should Require From a Cleaning Partner

ISO-aligned cleaning is not about frequency.

It is about discipline.

Facility managers responsible for mission-critical environments should require partners who demonstrate:

- HEPA-filtered equipment that captures fine particulate matter

- Anti-static and ESD-aware procedures

- Controlled access and containment during cleaning activity

- Documentation and verification—not improvisation

- Audit readiness tied to inspections and commissioning

These requirements move cleaning out of the janitorial category and into risk management.

Why ISO 14644-1 Matters More in Atlanta Than Ever

Atlanta continues to see rapid expansion in:

- Data centers and hyperscale infrastructure

- Advanced manufacturing and life sciences

- Healthcare and regulated environments

- High-value post-construction commissioning

As asset values rise, tolerance for contamination risk falls.

ISO 14644-1 is no longer an abstract standard.

It is the baseline expectation for facilities where uptime, compliance, and asset protection matter.

A Final Perspective for Facility Leadership

The most costly contamination events are rarely visible.

They emerge quietly—from overlooked subfloors, improper equipment, or well-intentioned but uninformed cleaning practices.

ISO 14644-1 exists to prevent those failures.

For Atlanta facility managers, understanding this standard is no longer optional.

It is part of responsible stewardship.

Clean environments are no longer defined by appearance.

They are defined by control.

Schedule a Critical Environment Risk Audit

If your facility operates in a mission-critical environment, the right first step is not a quote.

It is clarity.

A Critical Environment Risk Audit evaluates particle control, cleaning methodology, and exposure points before failure

occurs.

Because in ISO-governed environments, the cost of not knowing is always higher than the cost of preparation.